הצהרת פרטיות: הפרטיות שלך חשובה לנו מאוד. החברה שלנו מבטיחה לא לחשוף את המידע האישי שלך לכל אקסני עם ההרשאות המפורשות שלך.

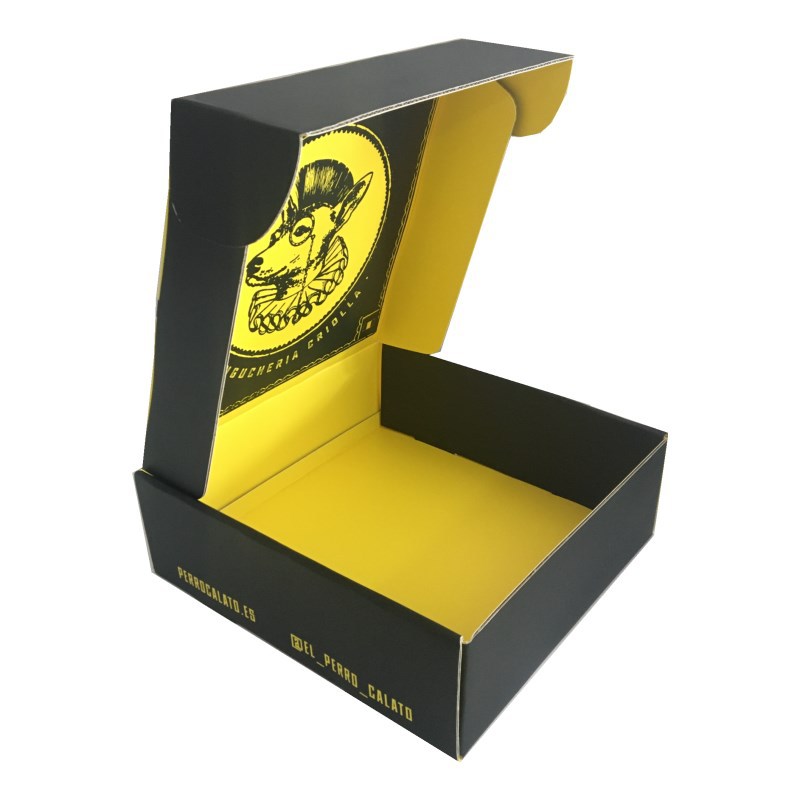

Liyang paper printing and packaging accept customized different style of paper packaging box, gift box, corrugated box, mailer box, shipping box:

Third, carton printing and forming process factors and technical requirements

Corrugated board flatness, physical strength, and whether there are flaws in the appearance of blemishes, pits, rib marks, stencil marks, creases, etc. are the basic conditions that affect the quality of low quantitative corrugated board printing and forming, but printing equipment and other equipment into the box Its own precision and controllability, as well as its production process and operating techniques, will also have a serious impact on the relative performance and quality of low-quantity corrugated cartons.

First, the factors of printing and boxing equipment directly affect the compressive strength of low-quantity corrugated boxes.

Printing machine, slotting machine, round press die cutting machine, paste box machine and other box equipment, the printing precision, parallelism of the printing roller, roller, roller, roller, roller, roller The magnitude of the error, such as the concentricity and the bearing runout, will have a direct impact on whether the low-quantitative board will maintain its strength during the boxing process. The smaller the error is, the smaller the effect is and the smaller the intensity is. On the contrary, the strength of the cardboard in the printing and the box will be partially destroyed and the compressive strength will be affected. Therefore, the machining accuracy and concentricity of the work rolls of each machine should be controlled at O. Below 05mm, the parallelism should be controlled below 0.15mm, and the bearing jump difference should be controlled at O. Within 05mm. The controllability of the box-forming equipment is whether the machine can flexibly and accurately adjust and control the various parameters required in the production process, such as: the size of the gap of the paper-feeding wheel, layout and roll, ink volume, and printing Pressure size and so on. Therefore, the production of low-volume corrugated cartons is not only a problem of the production line, but also should fully consider the performance and parameters of printing and other molding equipment, and whether it meets the production requirements. If the equipment performance does not reach, the quality of the low-quantity corrugated carton will not be guaranteed.

Second, the technical factors of printing and forming processes have an impact on the strength of low-quantity corrugated cartons.

Some paper box is corrugated board for shipping, some box for gift packaging.

The printing and forming technology requirements are firstly to properly control the gaps, pressures, and ink volume in each work, so as to prevent the cardboard from being damaged due to improper gaps and pressure during the production process. In particular, low-volume corrugated paperboard, because its flat compressive strength is much lower than that of high-quantitative paperboard, requires careful operation and strict control of technical parameters in production. Such as the amount of ink, the ink is too large, the printing effect will be poor; the amount of ink is too small, often in the operation will increase the printing pressure, so that the pressure between the printing plate and cardboard increases and the strength of the cardboard is damaged. Therefore, it is recommended that the amount of ink should be controlled at about 0.10mm; the feed roller gap, layout and roller gap, the gap between the paper rollers should be controlled at a thickness of -0.15mm-0.20mm according to the thickness of the board; layout and net roll The gap should be controlled at -0.10mm. Secondly, if a resin flexographic plate is used, attention should be paid to the uniformity of the flatness and elasticity of the liner in order to ensure the printing accuracy and the uniformity of the pressurization of the paperboard. Third, if die-cut cartons are used, care should be taken to ensure that the stiffness and distribution of the spring pads on the stencils will cause indentation or partial crushing of the cardboard and affect the compressive strength of the carton after molding. Fourth, in the paste box, nail box, and packaging, loading and unloading, and transportation, care should be taken to protect the carton to avoid the phenomenon that the carton is considered to cause creases, and the strength and appearance quality of the carton are affected.

IV. Some Opinions on Production and Use of Low Volume Corrugated Boxes

Given the importance of low-volume corrugated boxes for the current corrugated box manufacturing industry, I would like to discuss some of my suggestions regarding the production of low-volume corrugated cartons in light of my past experience. Low-volume corrugated cartons should be produced using high-strength base paper. According to the general requirements, the surface, the minimum paper should use B grade kraft linerboard, corrugated paper should generally use high-strength corrugated paper. The physical index of the corrugated board, single corrugated board should be at least to break more than 600Kpa, side pressure more than 4000N; double corrugated board should be at least to break more than 800Kpa, side pressure of 5500N or more, so as to basically meet the general cargo packaging requirements. At the same time, carton sizes should be considered as small as possible. According to the factors of physical properties and production technology, the surface area of the carton is generally not more than 0.4m2 in single-wall boxes, and not more than 0.8m2 in double corrugated boxes. It is best not to consider making large boxes and valuables boxes.

In addition, consideration should also be given to the use of products such as textiles, foods, household appliances, small electronics, and general daily necessities, etc., in the outer packaging of products with lighter interior contents, and other packaging products or inner packagings and their contents. Strong support of product packaging. In order to ensure the accumulation of cartons under pressure. Carton manufacturers should guide customers to pay attention to ventilation and environmental drying in the storage, packaging and transportation of cartons. Avoid moisture in the carton and affect its strength.

In my opinion, although low-volume corrugated cartons are the direction of development of paper packaging, users of cartons and cartons should consider and measure the process technology and the use of the cartons comprehensively. Can they be blindly and simply produced? Use a low volume corrugated carton. In order to truly promote the healthy development of low-volume corrugated cartons, it is necessary to grasp the production and use in a timely and appropriate manner as the structure of products in various industries changes and the distribution of product categories in each region.

November 12, 2024

November 10, 2024

October 21, 2024

October 31, 2024

October 30, 2024

שלח לחבר

November 12, 2024

November 10, 2024

October 21, 2024

October 31, 2024

October 30, 2024

שלח חקירה

Ms. Lily Yu

תל:86-769-82795922

Fax:86-769-85193253

טלפון נייד:+86 13580852389

אֶלֶקטרוֹנִי:admin@lyprinting.com

כתובת:Jiumenzhai Jiuzui New District Road, Humen Town, Dongguan City, Guangdong Province, 523999, China., Dongguan, Guangdong

אתר לנייד

הצהרת פרטיות: הפרטיות שלך חשובה לנו מאוד. החברה שלנו מבטיחה לא לחשוף את המידע האישי שלך לכל אקסני עם ההרשאות המפורשות שלך.

מלא מידע נוסף כך שיוכל ליצור איתך קשר מהר יותר

הצהרת פרטיות: הפרטיות שלך חשובה לנו מאוד. החברה שלנו מבטיחה לא לחשוף את המידע האישי שלך לכל אקסני עם ההרשאות המפורשות שלך.